Кратак резиме: Правилно одржавање торбе за планинарење је од суштинског значаја за очување перформанси, безбедности и интегритета материјала током времена. Зној, прашина, влага и неправилно сушење постепено слабе тканине, премазе, патент затвараче и носиве конструкције. Овај водич објашњава када и како очистити торбу за планинарење, како је правилно осушити и чувати и како одлуке о дуготрајној нези директно утичу на издржљивост, удобност и поузданост у стварној употреби на отвореном.

Зашто је правилно одржавање планинарске торбе важније него што мислите

После дугог дневног пешачења кроз влажне шуме, прашњаве стазе или влажне летње услове, већина планинара инстинктивно чисти своје чизме и пере одећу. Међутим, планинарска торба често остаје нетакнута. Ова навика постепено смањује функционални животни век ранца, чак и када споља изгледа прихватљиво.

A торба за планинарење није само текстилни контејнер. То је систем који носи оптерећење дизајниран да расподели тежину на рамена, леђа и кукове док штити основну опрему од излагања околини. Временом, зној, фина прашина, песак, УВ зрачење и неправилно сушење полако слабе тканине, деградирају премазе и угрожавају структурне компоненте. Ове промене су ретко изненадне. Уместо тога, тихо се акумулирају све док патент затварачи не покваре, траке не изгубе еластичност, облоге се љуште или задње плоче не добију упоран мирис и крутост.

Правилно одржавање се не односи на козметички изглед. Ради се о очувању перформанси, одржавању сигурносних маргина и продужењу интегритета материјала током година употребе. Овај водич објашњава како правилно чистити, сушити, складиштити и одржавати торбе за планинарење, на основу науке о материјалима, стварних сценарија на отвореном, принципа тестирања издржљивости и еволуирајућих индустријских стандарда.

Испирање унутрашњости планинарског ранца чистом водом помаже у уклањању зноја, прљавштине и остатака који временом могу оштетити тканине, премазе и патент затвараче.

Разумевање материјала за планинарске торбе пре чишћења

Уобичајене тканине које се користе у торбама за планинарење

Већина модерних планинарских торби је првенствено направљена од синтетичких тканина најлон и полиестер. Ови материјали су одабрани због њиховог односа снаге и тежине, отпорности на хабање и понашања влаге.

Најлон се обично специфицира коришћењем дениера као што су 210Д, 420Д, 600Д или 900Д. Дениер се односи на масу предива на 9.000 метара. Већи деније обично означава дебље предиво и већу отпорност на хабање, али и повећану тежину.

У правим планинарским торбама:

-

210Д најлон се често користи у лаганим дневним паковањима и панелима са ниским стресом

-

420Д најлон побољшава отпорност на хабање за приближно 30 до 40 процената у поређењу са 210Д

-

Најлон од 600Д до 900Д се често примењује на основе паковања и зоне високог хабања

Полиестерске тканине се такође широко користе, посебно у подручјима са јаким излагањем сунцу. Полиестер задржава затезну чврстоћу боље од најлона под продуженим УВ зрачењем, иако обично нуди нешто нижу отпорност на кидање на истом нивоу денијера.

Методе чишћења које су безбедне за једну врсту тканине могу убрзати хабање друге. Разумевање састава тканине је неопходно пре наношења воде, детерџената или механичког дејства.

Премази и површински третмани који утичу на чишћење

Већина торбе за планинарење ослањају се на унутрашње или спољашње премазе за постизање водоотпорности. Најчешћи третмани укључују полиуретанске (ПУ) премазе, термопластичне полиуретанске (ТПУ) ламинате и издржљиве водоодбојне (ДВР) завршне слојеве нанете на спољашњу тканину.

ПУ премази се постепено разграђују хидролизом, хемијском реакцијом убрзаном топлотом и влагом. Агресивни детерџенти, продужено намакање или прање топлом водом могу повећати стопу квара премаза за 25 до 40 процената током поновљених циклуса чишћења.

ДВР третмани су посебно осетљиви на сурфактанте и омекшиваче. Неправилно прање може смањити ефикасност водоодбојности за више од 50 процената након једног прања. Због тога конвенционални детерџенти за веш нису погодни за одржавање торби за планинарење.

Структурне компоненте које захтевају посебну пажњу

Осим тканина и премаза, торбе за планинарење садрже структурне компоненте које су веома осетљиве на влагу и топлоту. То укључује задње панеле од пене, алуминијумске држаче, пластичне лимове оквира, ојачане зоне шавова и носиву траку.

Води заробљеној унутар панела од пене може бити потребно између 24 и 72 сата да потпуно испари ако су услови сушења лоши. Продужена влага слаби адхезивне везе, подстиче раст микроба и убрзава разградњу пене. Временом, ово смањује удобност ношења и перформансе вентилације леђа.

Када треба да очистите торбу за планинарење?

Учесталост чишћења заснована на интензитету употребе

Учесталост чишћења треба да буде одређена нивоом изложености, а не календарским временом. Торба за планинарење која се користи на сувим, кратким стазама захтева много мање одржавања од оног који је изложен блату, зноју или обалном окружењу.

Опште смернице засноване на употреби на терену:

-

Лагана употреба: чишћење сваких 8 до 12 излазака

-

Умерена употреба: чишћење сваких 4 до 6 излазака

-

Тешка употреба: чишћење након сваког путовања

Прекомерно чишћење може бити једнако штетно као и занемаривање. Прекомерно прање убрзава замор влакана, деградацију премаза и напрезање шавова.

Знаци да је планинарској торби потребно хитно чишћење

Одређени показатељи указују на то да одлагање чишћења може проузроковати дуготрајну штету. Упорни мирис сигнализира активност бактерија унутар слојева пене и тканине. Видљиве мрље од соли указују на талог зноја који привлачи влагу и слаби влакна. Акумулација песка у близини патент-затварача и шавова повећава хабање и механичко хабање.

Кристали соли који су остали од осушеног зноја могу повећати локализовану крхкост влакана за 10 до 15 процената током времена, посебно у областима са високом савитљивошћу као што су нараменице.

Водич корак по корак за безбедно чишћење планинарске торбе

Припрема пре чишћења

Пре прања а преносиви планинарски ранац, све преграде треба потпуно испразнити. Уклоњиве компоненте као што су алуминијумски држачи, пластични оквири или одвојиви појасеви за кукове треба извадити ако је могуће. Све траке и копче треба олабавити да би се смањила напетост током чишћења.

Растресити песак и остатке треба отрести или обрисати. Прескакање овог корака омогућава да се абразивне честице самељу о тканину и шавове током прања.

Ручно прање у односу на машинско прање

Прање руку је пожељна метода за планинарске торбе. Омогућава контролисано чишћење без уношења прекомерног механичког напрезања.

Машинско прање може деформисати структуре од пене, попуцати пластичне копче и ослабити шавове на шавовима са великим оптерећењем. Лабораторијско испитивање замора текстила показује да поновљено механичко мешање може смањити чврстоћу шава до 20 процената.

Ако је машинско прање неизбежно, треба користити само хладну воду, уз нежни или ручно прање и минималну брзину центрифуге.

Одабир правих средстава за чишћење

Треба користити само благе сапуне без детерџента или неутрална пХ средства за чишћење. Увек треба избегавати јаке алкалне детерџенте, избељиваче, омекшиваче и средства за чишћење на бази растварача.

Ефективна концентрација је обично 5 до 10 милилитара чистача по литру воде. Веће концентрације не побољшавају ефикасност чишћења и уместо тога убрзавају деградацију премаза.

Сушење планинарске торбе на прави начин

Зашто неправилно сушење узрокује дуготрајна оштећења

Сушење је један од најпотцењенијих корака у одржавању планинарских торби. Многи ранчеви који изгледају структурално здрави прерано покваре због неправилног сушења, а не због лоше конструкције или тешке употребе.

Вишак топлоте је посебно штетан. Полиуретански премази почињу да омекшавају и одвајају се на температурама изнад приближно 50°Ц. Излагање радијаторима, сушилицама или директној сунчевој светлости може изазвати појаву пликова, љуштења или пуцања унутрашњих премаза. Када овај процес почне, отпорност на воду брзо опада и не може се у потпуности вратити.

Влага заробљена унутар панела од пене је још један велики проблем. Пена која се користи у задњим панелима и нараменицама је дизајнирана да обезбеди амортизацију док дозвољава проток ваздуха. Када влага остане заробљена, она слаби адхезивне везе и ствара идеално окружење за раст бактерија и гљивица. То доводи до постојаног мириса, смањене удобности и постепеног структуралног колапса пене.

Препоручене методе сушења

Најсигурнији начин сушења је природно сушење на ваздуху у засјењеном, добро проветреном окружењу. Торба треба да буде потпуно отворена, са одељцима који су раширени како би се максимизирао проток ваздуха. Окретање вреће наопачке током почетне фазе сушења помаже да влага изађе из унутрашњих слојева.

Качење торбе уместо да је положи равно омогућава гравитацији да помогне одводњавању. У зависности од влажности и протока ваздуха, потпуно сушење обично траје између 12 и 36 сати. У влажним срединама сушење може трајати дуже, а стрпљење је неопходно.

Вештачки извори топлоте никада не би требало да се користе, чак и ако се сушење чини споро. Дуготрајна оштећења изазвана топлотом далеко су већа од погодности бржег сушења.

Затварачи, копче и одржавање хардвера

Чишћење и одржавање рајсфершлуса

Зипперс спадају међу компоненте планинарских торби које су највише склоне кваровима, не због лошег дизајна, већ због контаминације. Фини песак и честице прашине се акумулирају између зубаца затварача и унутар клизача. Сваки пут када се затварач повуче, ове честице делују као абразиви, повећавајући хабање.

Чак и мале количине песка могу узроковати значајно повећање отпорности на затварач. Студије о механичком хабању показују да абразивне честице могу убрзати хабање зубаца затварача за 30 до 40 процената током времена.

Након прашњавих или пешчаних шетњи, патент затвараче треба нежно испрати чистом водом. За уклањање уграђених честица може се користити мекана четка. У сувим окружењима, повремено подмазивање мазивом специфичним за патент затварач помаже у одржавању несметаног рада. Претерано подмазивање треба избегавати, јер привлачи прљавштину.

Копче, системи за подешавање и хардвер за оптерећење

Пластичне копче и компоненте за подешавање су осетљиве и на температуру и на излагање УВ зрачењу. Продужено излагање сунцу постепено смањује отпорност на удар, док ниске температуре повећавају ломљивост.

Испод приближно -10°Ц, многе пластичне копче постају склоније пуцању под оптерећењем. Редовна инспекција је неопходна, посебно пре зимских планинарења или путовања са тешким теретом. Сви знаци избељивања или пуцања напрезања указују на смањену сигурност конструкције.

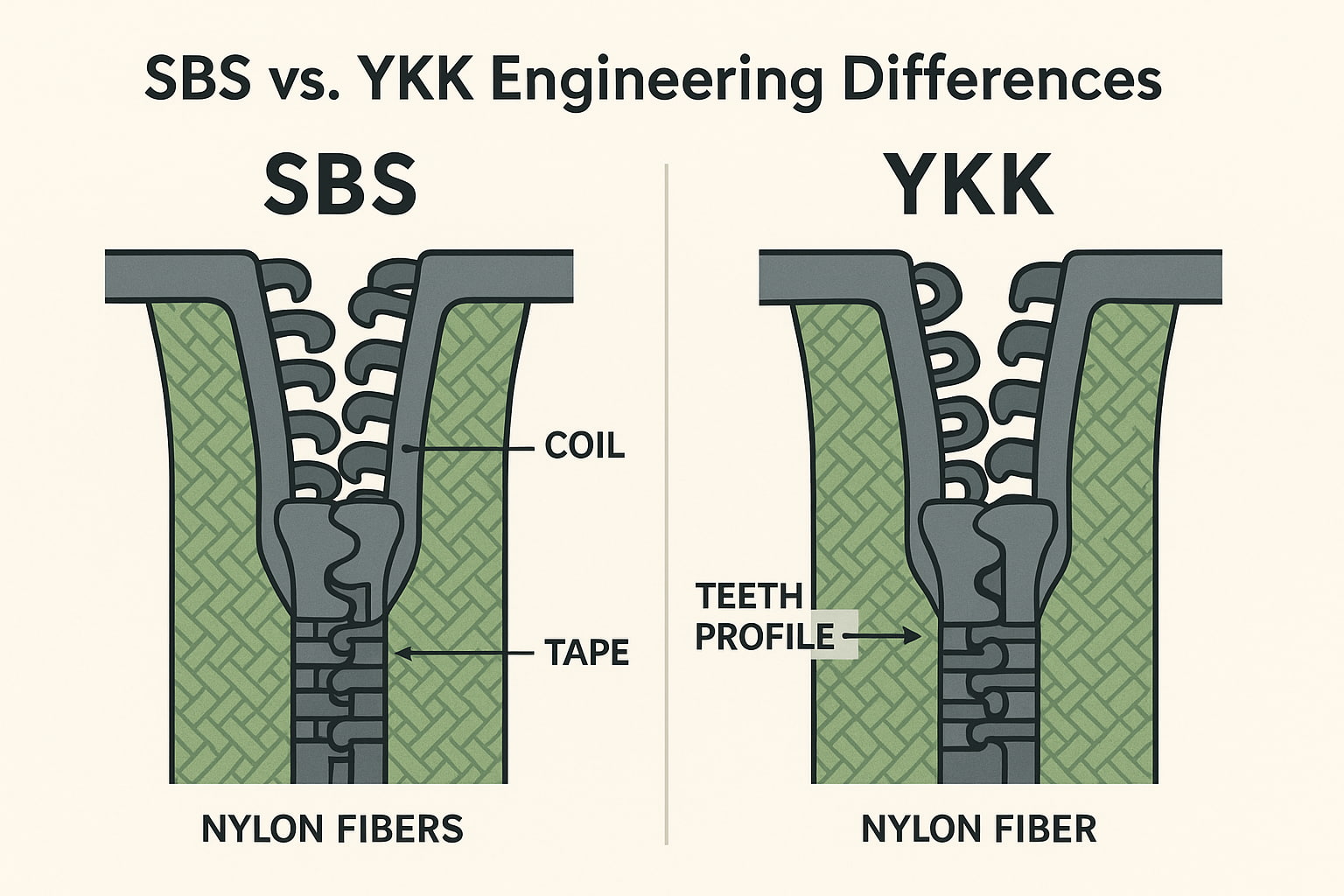

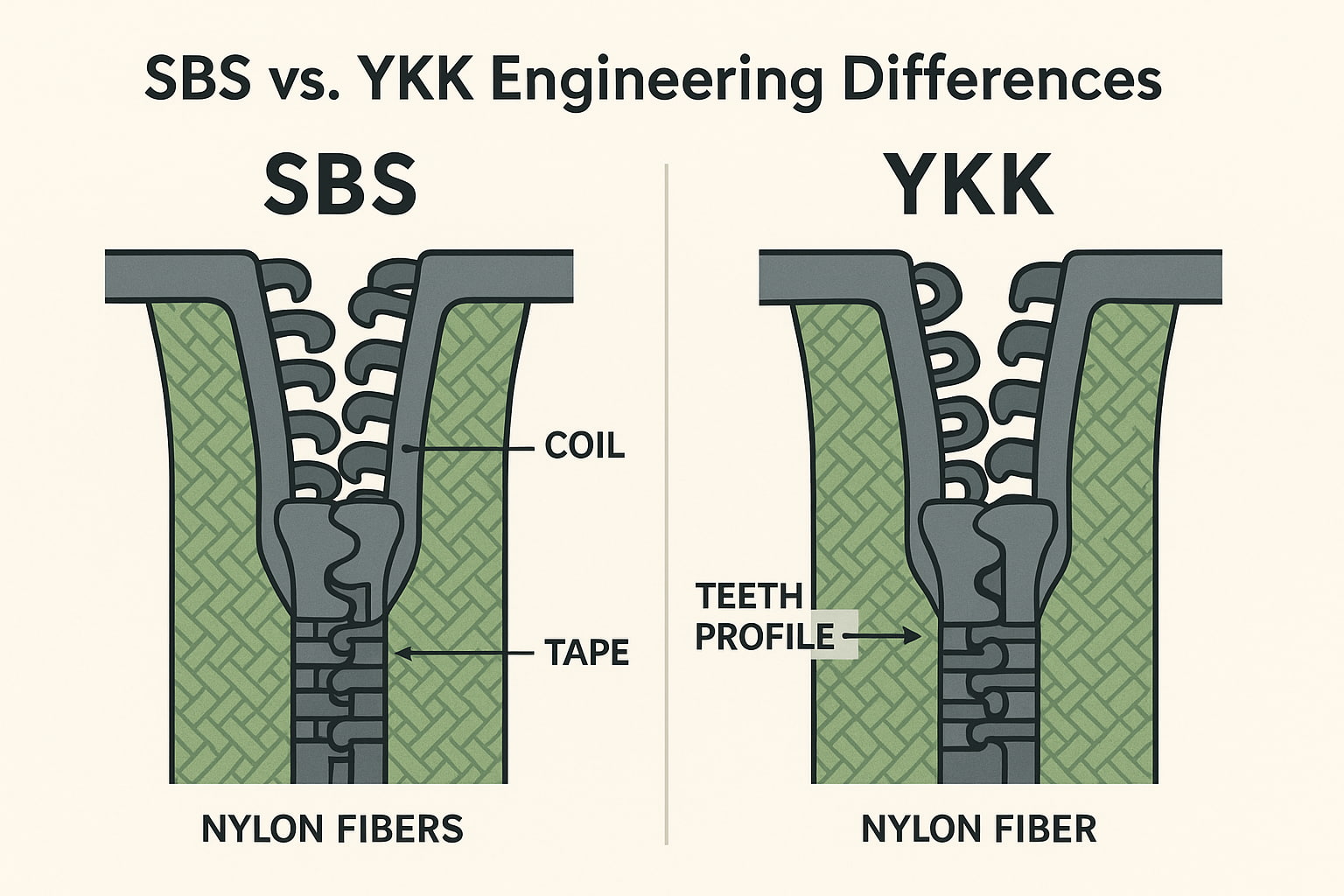

Технички пресек који илуструје структурне разлике између СБС и ИКК система затварача, фокусирајући се на облик завојнице, профил зубаца и састав траке који се користи у торбама за планинарење високих перформанси.

Контрола мириса и управљање хигијеном

Зашто торбе за планинарење развијају постојане мирисе

Развој мириса није само питање чистоће. Зној садржи соли, протеине и масне киселине које продиру у слојеве тканине и пене. Бактерије се хране овим једињењима, производећи нуспроизводе који изазивају мирис.

Једном када бактерије колонизују подлогу од пене, само чишћење површине је често недовољно. Без темељног прања и потпуног сушења, мириси се брзо враћају, понекад у року од неколико сати након употребе.

Технике безбедног уклањања мириса

Најефикаснији метод контроле мириса је комбинација темељног прања и продуженог сушења. У неким случајевима, разблажени кисели раствори као што су купке са сирћетом ниске концентрације могу помоћи у неутрализацији бактерија које изазивају мирис. Концентрације треба да остану ниске како би се избегло оштећење тканине.

Циркулација ваздуха је подједнако важна. Дуготрајно проветравање између употребе значајно смањује раст бактерија. Не препоручује се маскирање мириса спрејевима или мирисима, јер не утиче на основну микробну активност и може погоршати задржавање влаге.

Дуготрајно складиштење и сезонско одржавање

Како чувати торбу за планинарење између годишњих доба

Неправилно складиштење је чест узрок прераног квара ранца. Торбе за планинарење никада не треба чувати док су влажне, стиснуте или изложене директној сунчевој светлости.

Идеални услови складиштења укључују:

-

Релативна влажност испод 60 процената

-

Стабилне температуре без екстремне топлоте

-

Минимална компресија пене и структурних компоненти

Окачење торбе или складиштење лабаве напуњене материјалом који дише помаже у очувању облика и отпорности подлоге. Дуготрајна компресија смањује капацитет одбијања пене и мења перформансе расподеле оптерећења.

Контролна листа предсезонске инспекције

Пре почетка нове сезоне планинарења, темељна инспекција помаже да се рано идентификују потенцијални проблеми. Кључне тачке укључују глаткоћу затварача, еластичност каиша, интегритет шавова у зонама високог напрезања и општу стабилност рама.

Тестирање торбе под условима малог оптерећења омогућава да проблеми испливају на површину пре него што постану критични током стварне употребе.

Поправити или заменити? Познавање разлике

Уобичајени проблеми који се могу решити

Многи уобичајени проблеми са торбом за планинарење се могу поправити. Мање огреботине на тканини, лабави шавови и чврсти патентни затварачи се често могу решити основним одржавањем или професионалним услугама поправке.

Брзе поправке спречавају да мали проблеми ескалирају у структурне кварове.

Када је замена сигурнији избор

Одређени проблеми указују на то да је замена сигурнија опција. То укључује напукнуте или деформисане оквире, распрострањено раслојавање премаза и панеле од пене који су се трајно срушили.

Када носиви систем више не распоређује тежину равномерно, ризик од повреда се значајно повећава. У овој фази, одржавање не може да врати оригиналне перформансе.

Трендови индустрије у издржљивости и нези торби за планинарење

Иновације материјала и дуговечност

Индустрија на отвореном се све више фокусира на материјале који нуде већу отпорност на хабање при мањој тежини. Модерне тканине имају за циљ да постигну више циклуса абразије по граму, побољшавајући издржљивост без повећања масе паковања.

Побољшане технологије адхезије премаза смањују љуштење и хидролизу, док напредак у формулацијама пене повећава дугорочну отпорност.

Одрживост и регулаторна разматрања

Прописи о животној средини преобликују и праксу производње и неге. Ограничења штетних хемикалија утичу на формулације премаза и препоручена средства за чишћење.

Потрошачи се све више подстичу да продуже животни век производа кроз одговарајућу негу, а не честу замену, усклађујући праксу одржавања са циљевима одрживости.

Уобичајене грешке у одржавању које праве планинари

Најчешће грешке укључују претерано чишћење, коришћење погрешних детерџената, сушење топлотом, игнорисање малих проблема са хардвером и складиштење кеса у влажном окружењу.

Свака грешка убрзава деградацију материјала и смањује функционални век трајања.

Закључак: Правилна нега продужава перформансе, а не само животни век

Одржавање торбе за планинарење није везано за изглед. Ради се о очувању перформанси, удобности и безбедности. Пажљиво чишћење, пажљиво сушење, редовна контрола и правилно складиштење осигуравају да торба за планинарење настави да функционише како је дизајнирана.

Уз правилно одржавање, добро направљена планинарска торба може остати поуздана годинама, подржавајући безброј миља истраживања на отвореном.

ФАК

1. Колико често треба да чистим своју планинарску торбу?

Већина торбе за планинарење треба чистити сваких 4 до 12 излазака, у зависности од изложености зноју, прашини, блату и влази. Торбе које се користе у условима влажне, блатњаве или јаког зноја могу захтевати чишћење након сваког путовања како би се спречило пропадање материјала и накупљање мириса.

2. Могу ли да перем торбу за планинарење у машини за веш?

Машинско прање се генерално не препоручује, јер механичко мешање може оштетити облоге од пене, шавове, премазе и хардвер. Ручно прање благим, неутралним средствима за чишћење је најсигурнија опција за очување структуре и дуготрајне трајности.

3. Колико времена је потребно да се планинарска торба потпуно осуши?

Сушење на ваздуху обично траје између 12 и 36 сати, у зависности од влажности, протока ваздуха и конструкције вреће. Потпуно сушење је неопходно пре складиштења како би се спречио раст буђи, стварање мириса и оштећења пене или премаза.

4. Шта узрокује да рајсфершлуси за планинарске торбе покваре?

Отказивање затварача је обично узроковано накупљањем песка и песка, недостатком редовног чишћења и прекомерном силом повлачења. Рани знаци укључују повећан отпор или неравномерно кретање, што се често може решити благовременим чишћењем и одржавањем.

5. Када треба да заменим своју планинарску торбу уместо да је поправљам?

Замена се препоручује када структурне компоненте као што су рамови, панели од пене или заштитни премази покваре и више не могу да подржавају безбедну расподелу оптерећења. Наставак употребе у овим условима повећава ризик од нелагодности и повреда.

Референце

-

Трајност и нега тканине ранца, часопис за истраживање текстила, др Роџер Баркер, Државни универзитет Северне Каролине

-

Деградација полиуретанског премаза у текстилу на отвореном, Јоурнал оф Апплиед Полимер Сциенце, Америчко хемијско друштво

-

Системи за ношење терета и ергономија ранца, Јоурнал оф Хуман Кинетицс, Међународно друштво за биомеханику

-

Смернице за одржавање опреме на отвореном, Медицинско друштво Вилдернесс

-

Ефекти излагања УВ зрачењу на синтетичка влакна, деградацију и стабилност полимера, Елсевиер

-

Испитивање отпорности на хабање тканих тканина, АСТМ Комитет за текстилне стандарде

-

Формирање мириса у синтетичким пенама, Јоурнал оф Индустриал Мицробиологи

-

Одржива нега производа у опреми на отвореном, Еуропеан Оутдоор Гроуп

Како правилно одржавање обликује дугорочне перформансе торби за планинарење

Торба за планинарење одржавање није козметичка рутина већ дугорочна стратегија учинка. Одлуке о чишћењу, сушењу и складиштењу директно утичу на то како тканине, премази, подметачи од пене, патентни затварачи и структурне компоненте старе под сталним излагањем на отвореном. Када се одржавање занемари, мале промене материјала се акумулирају и постепено смањују удобност ношења, водоотпорност и стабилност оптерећења.

Из функционалне перспективе, ефикасно одржавање даје одговоре на низ практичних питања уместо да следи фиксну контролну листу. Колико често треба чистити торбу за планинарење зависи од изложености околини, накупљања зноја и интензитета употребе. Зашто су нежне методе чишћења важне постаје јасно када се узме у обзир деградација премаза, замор шавова и распад пене изазван топлотом и агресивним детерџентом. Који метод сушења буде изабран одређује да ли ће влага остати заробљена унутар структуралних слојева, убрзавајући стварање мириса и квар материјала.

Такође постоје јасни компромиси и опције у пракси одржавања. Прекомерно чишћење убрзава хабање, док недовољно чишћење дозвољава загађивачима да оштете влакна и хардвер. Машинско прање може уштедети време, али повећава механички стрес, док прање руку чува структурни интегритет. Дугорочни избори складиштења—као што су избегавање компресије и контрола влажности—помажу у одржавању отпорности пене и тачности расподеле оптерећења током више сезона.

На нивоу индустрије, модерна нега торби за планинарење одражава шире трендове ка издржљивости, одрживости и усклађености са прописима. Иновације материјала имају за циљ повећање отпорности на хабање и адхезију премаза, док еволуирајући стандарди заштите животне средине утичу на препоручена средства за чишћење и понашање потрошача. Као резултат тога, правилно одржавање је у складу не само са индивидуалним циљевима перформанси, већ и са одговорном употребом производа и дужим животним циклусом опреме.

На крају крајева, добро одржавана планинарска торба функционише као невидљиви систем подршке. Када се одлуке о чишћењу, сушењу и складиштењу доносе са разумевањем, а не са навиком, ранац наставља да ради како је дизајниран – подржавајући безбедност, удобност и поузданост током година коришћења током планинарења уместо да постане рана тачка квара.