Полиетилен терефталат (ПЕТ) је термопластични полимерни материјал који се користи у врећама због своје високе чврстоће, отпорности на хабање, лаганих својстава, својстава против бора и хидрофобности. Широко се користи у текстилне, амбалажне, аутомобилске и друге области. Основне карактеристике полиестера укључују високу затезну чврстоћу, ниску густину, очување облика против бора и УВ отпорност. Такође се користи у дневним ранчевима, путне торбе и еколошке торбе. Међутим, он има недостатке као што су ниска цена, лоша пропусност и неразградивост. Будући трендови укључују иновације и одрживи развој.

Основне информације о полиестерском материјалу

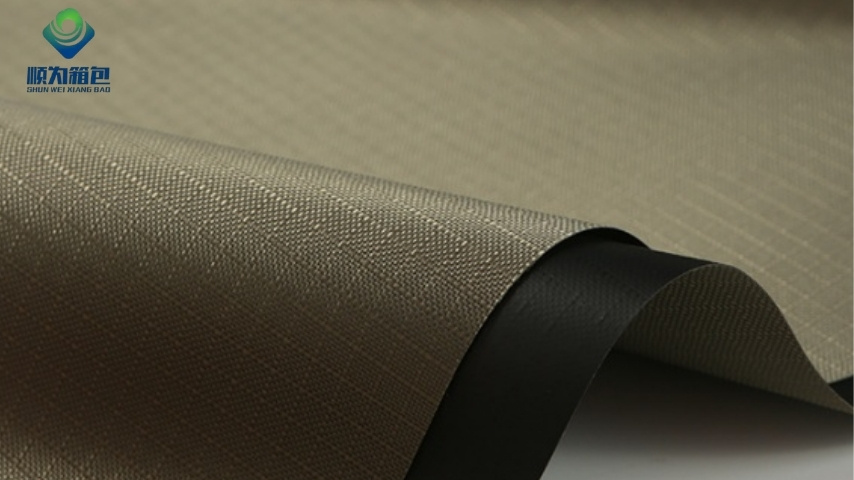

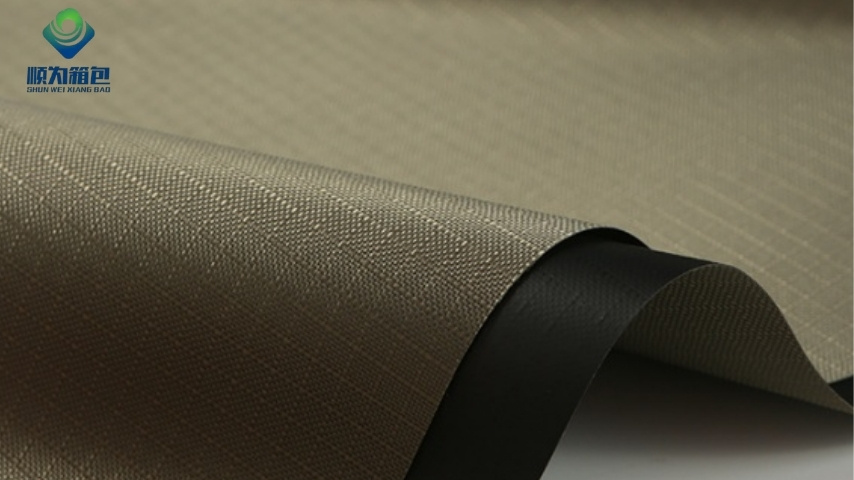

полиестер. Хемијско име је полиетилен терефталат (ПЕТ), то је термопластични полимерни материјал синтетизован од деривата нафте.

- Историјска позадина: Полиестер су измислили британски хемичари 1941. године и постао је најраспрострањеније синтетичко влакно на свету због индустријске масовне производње 1970-их.

- Сировине и производња: фтална киселина добијена из нафте и етилен гликол се користе као сировине за формирање полимера дугог ланца полимеризацијом, а затим се влакна праве центрифугирањем.

- Тржишна позиција: више од 80% светске производње синтетичких влакана, која се широко користе у текстилу, амбалажи, аутомобилској индустрији и другим областима.

Примена полиестерских материјала у врећама

Основне карактеристике полиестера

- Физичке карактеристике

- Висока чврстоћа и отпорност на хабање: висока затезна чврстоћа, отпорност на трење, погодна за честу употребу врећа.

- Лагана: Мала густина (1,38 г/цм³), смањује тежину инклузије.

- Очување облика против бора: није лако деформисати, брзо се враћа у првобитно стање након преклапања.

- Хидрофобност: ниска апсорпција воде (само 0,4%), није лако обликовати у влажном окружењу.

- Хемијске карактеристике

- Отпорност на киселину и алкалну корозију: стабилан на слабе киселине и слабе алкалије, прилагођава се различитим окружењима.

- Отпорност на светлост и топлоту: тачка топљења око 260°Ц, УВ отпорност је боља од најлона.

- Предност обраде

- Лако се фарба, вруће пресовање, подржава сложен дизајн (као што је ласерско сечење, високофреквентно утискивање).

Сценарио примене полиестера у области торби

- Дневни ранчеви и путне торбе

- Исплативе полиестерске тканине (као што је 600Д полиестер) се често користе у студентским и путничким руксацима, са ПВЦ премазом за побољшање водоотпорности.

- Кућиште познатог бренда: Неки од СамсонитеЛагани кофери су направљени од мешавине полиестера.

- Спортска торба на отвореном

- Побољшане водоотпорне перформансе посебним третманом (као што је ПУ премаз), погодне за торбе за планинарење и торбе за вожњу.

- Случај у тачки: Тхе Нортх ФацеЛагана торба за планинарење направљена је од оксфордске тканине од полиестера високе густине.

- Модне и еколошке торбе

- Рециклирани полиестер (рПЕТ) се користи у еколошким торбама за куповину, као што је серија „Рецицлед Цоллецтион” Патагоније.

- Имитација коже од полиестера од микровлакана (нпр. УлтраСуеде®) за луксузне ташне уместо праве коже.

- Функционални дизајн

- Помешајте са најлоном да бисте побољшали отпорност на кидање или додајте еластична влакна (као што је спандекс) да бисте направили торбе за складиштење које се могу увлачити.

Предности и мане поређења полиестерских торби

| Предност | Недостатак |

| Ниска цена, погодна за масовну потрошњу | Слаба пропусност, лако се спари |

| Лако се чисти, отпоран на мрље | Трење узрокује да статички електрицитет апсорбује прашину |

| Светле боје и дуготрајни отисци | Није природно разградиво (500 година) |

| Није природно разградиво (500 година) | Системи за рециклажу још увек нису у потпуности доступни |

Будући трендови: Иновације и одрживи развој

- Пробој технологије заштите животне средине

- Рециклирани полиестер (рПЕТ):Смањите потрошњу уља рециклирањем пластичних боца и коришћене одеће у влакна. Брендови као што је Адидас планирају да користе рециклирани полиестер до 2030. године.

- Био на бази полиестера:Смањите свој угљенични отисак коришћењем обновљивих извора као што је кукурузни скроб, као нпр Сорона® влакна.

- Надоградња перформанси

- Самочистећи премаз:Хидрофобна технологија лотосовог листа смањује захтеве за чишћење.

- Паметна влакна:Уграђено проводљиво предиво, торба за подршку и веза за електронски уређај (као што је праћење против крађе).

- Модел циркуларне економије

- Брендови покрећу програме „траде-ин“, као што су Фреитагсистем за рециклажу врећа.

- Иновација дизајна

- Модуларна полиестерска торба (нпр Тимбук2дизајн одвојивих компоненти) за продужење животног циклуса производа.

Комплетан водич за полиестер

полиестер је и даље материјал избора за индустрију кеса због високих перформанси и пластичности. У будућности, кроз надоградњу технологије заштите животне средине и иновативног дизајна, очекује се да ће се полиестер ослободити „није еколошки прихватљив” и постати основни носилац одрживе моде.

Примена полиестерских материјала у врећама

Примена полиестерских материјала у врећама

Комплетан водич за полиестер

Комплетан водич за полиестер